/great design that's easy to swallow

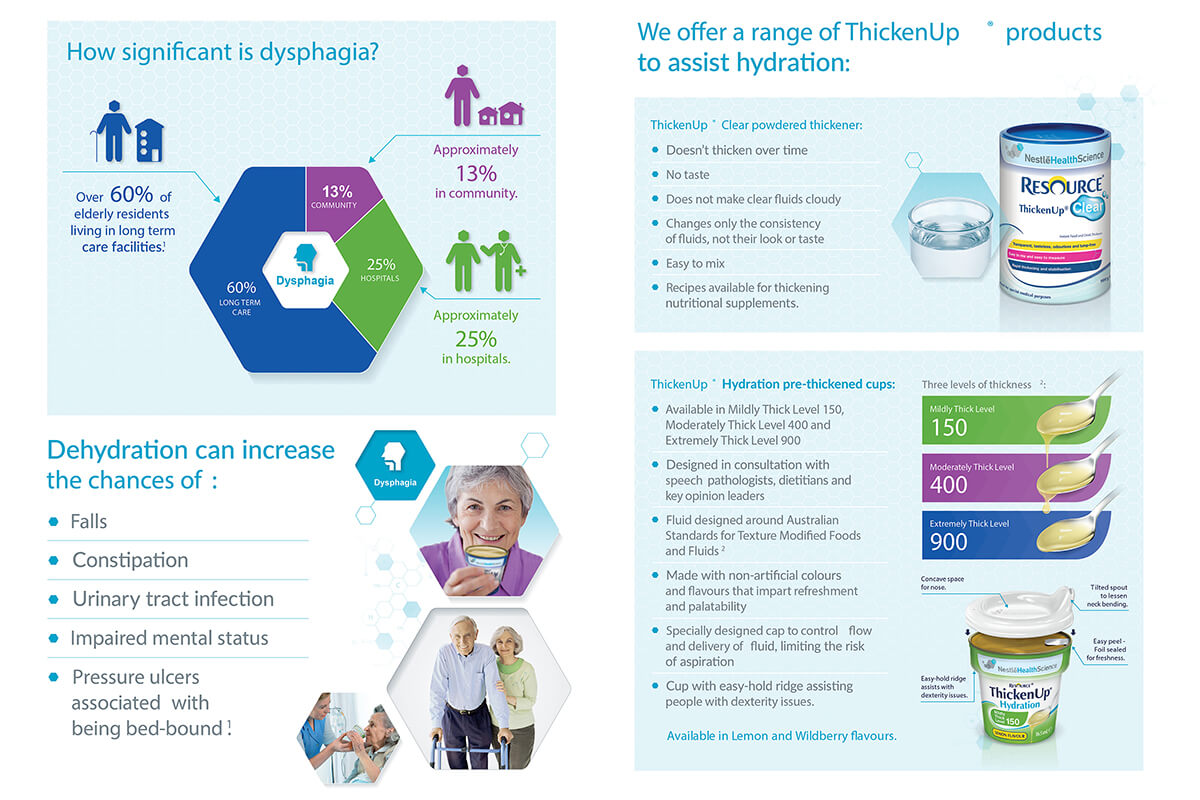

Dysphagia is the medical term for the symptom of difficulty in swallowing. Those who suffer from Dysphagia and rely on thickened liquids are clinically dehydrated. Dehydration can have severe consequences, as it increases the chances of a number of compounding health issues, including falls, risk of renal failure, constipation, urinary tract infection, impaired mental status, respiratory infection, and poor muscle strength.

Dysphagia occurs in approximately 13% of the community, 25% within hospitals, and over 60% of elderly residents living in long term care facilities. Nestlé Health Science developed Resource® ThickenUp® Hydration for people who may be afflicted by a variety of disabilities or impairment, but in particular for those suffering from Dysphagia. qDesign were called upon to assist with designing sipper cap that was suitably tailored for the viscosity of product, and in turn provide controlled product consumption to dysphagia sufferers.

Nestlé Health Science developed Resource® ThickenUp® Hydration in consultation with speech pathologists, dieticians, and key opinion leaders. The design process would need to carefully consider the various potential impairments of the end user, including arthritis, a lack of grip strength and dexterity, a lack of oral sensitivity, and the very real risk of choking during consumption.

A level of definition had already been given to the project. Nestlé Health Science had chosen a shrink sleeved composite cup with a plastic body, rolled metal rim, and foil seal. The missing piece of the puzzle was the sipper lid, which needed to be easily applied to the cup, and provide comfortable and controlled consumption of the levels 150 and 400 product. The lid was to include a projected spout feature that would allow the consumer to receive a controlled flow of product and limit the amount of dexterity required to consume from start to finish.

A number of Consumer Journey Maps were used to explore modes of interaction with the pack from point of opening to point of consumption. Key areas of design focus were ease of assembly, spill and leak resistance, and providing a pronounced sipper feature to facilitate intuitive and controlled consumption of the product. Early ideation considered more complex designs and mechanisms, followed by refined concept development steering more towards a simplified solution. Ordinarily, a thin walled injection molded lid of this kind would be designed as a nesting and stackable component for maximum production and freight efficiencies. On this occasion, the benefit of a tilted and ergonomic spout to the target consumer outweighed that of production efficiency.

Rapid prototyping provided a very effective means of testing and review for a number of design iterations. With the general sipper lid design format locked in place, we were then able to efficiently explore variations of sipper length and angle. Prototyping these designs allowed for interim review of the fitment of the lid to the can end, and a better understanding of product delivery through the sipper feature.

After review of prototypes, a single cavity injection mold pilot tool was commissioned. This allowed for samples to be produced in the production process and LDPE material, and a more rigorous review of lid application and leak proofing performance. These samples also allowed Nestle Health Science to run controlled trials of the product and ensure that it was providing a safe and effective consumption experience to their target consumers.

With the pilot samples flying through consumer trials with a glowing review, it was full steam ahead with the commissioning of production tooling with only minimal design refinements. The molded sipper lids were packaged and supplied in 24pc cartons, which would provide easy distribution, unpacking and selection for assembly with the ThickenUp® product as required.

Ergonomic and Accessible Design

The cup with easy hold ridge & easy peel foil is designed to help patients with compounding health issues such as arthritis. The unique sipper lid features a concave nose clearance and tilted spout to allow the cup to be tipped with minimal neck bending. A transparent lid fits snugly to prevent leaks and spills and allows users to see how much has been consumed. The sipper aperture is tailored for the pre-thickened product viscosity and includes ribbed profiles to provide sensory feedback to Dysphagia patients with poor feeling or sensitivity, informing them that the spout has been inserted fully into their mouth. Perforated easy-open shippers fit neatly into a home pantry or onto food service shelving spaces.

Functional Material Selection

The material chosen for this sipper lid is a soft and pliable low-density polyethylene (LDPE). This material feels comfortable in the mouth, and by its soft and pliable nature eliminates the risk of any sharp areas that may be caused from product burrs, flashing or from the injection gating point itself. The pliable material provides easy application to the Thicken-Up cup and is transparent in appearance to have visibility of the product contents and whether they were finished. LDPE also means that should a user chew or bite on the sipper feature it will not crack or shatter in their mouth. LDPE also allows for a soft, smooth surface finish.

Power to the Patient – Hydration without assistance

The Nestlé ThickenUp® sipper lid’s material choice, size, shape and design features provide an easy to consume pack for the high viscosity products. The pack design is easy to hold and provides a controlled delivery, allowing for use outside of care facilities. This, in turn, allows patients to receive hydration without assistance, to optimise fluid intake, and reduce compounding heath issues. The overall result delivers a level of consumer convenience that for many of us is taken for granted, but was previously unavailable to a small but significant consumer group, particularly those who suffer the condition of dysphagia.

2017 - PIDA - Winner | Health, Beauty & Wellness Category

2017 - PIDA - High Commendation | Food Catagory

2016 - Good Design® Finalist - Communication Design | Packaging